Your Trusted Partner for TMV Servicing

Thermostatic mixing valves play a critical role in controlling hot water temperature at taps, showers and outlets. When they are not serviced correctly, performance can drift over time, increasing the risk of scalding, user complaints and non compliance with water safety guidance. Maintaining a safe water temperature at outlets is essential in healthcare, education, residential and commercial settings, particularly where vulnerable users may be present.

TMV servicing ensures valves continue to blend hot and cold water accurately, respond quickly to changes in supply conditions and operate correctly if a fault occurs. It is an essential part of managing hot water systems safely, particularly in buildings where vulnerable users may be present.

At Titan Water, we provide professional TMV testing and maintenance for healthcare, education, commercial and industrial buildings across the UK. Our engineers carry out thorough testing, cleaning and calibration to ensure thermostatic mixing valves operate safely, efficiently and in line with current guidance, including HSG274 Part 2 and NHS Model Engineering Specification requirements.

Our approach is practical and transparent. We assess temperature accuracy, response time and failsafe operation at each valve, carry out any necessary adjustments or internal cleaning, and provide clear records with straightforward recommendations. Whether TMVs are serviced as part of a routine maintenance programme or following a risk assessment, we focus on keeping hot water systems safe, reliable and compliant.

Nationwide Service

Reliable Expertise Wherever You Are

Our experienced management team operate from the Titan head office near Liverpool, but while our roots are in the North West, our reach goes far beyond it. Our engineers carry out TMV servicing & replacement projects across the UK through a network of trained regional specialists. Whether it’s a hospital in Cumbria, a care home in Birmingham, or a school in South Wales, we’ve been there - and we know how important reliable TMV performance is for user safety.

If you’ve had scalding incidents, temperature failures, or just want confidence that your valves are working correctly, the team at Titan are always happy to help with clear, honest advice.

Your Questions Answered

What Is TMV Servicing?

TMV servicing is the process of testing, cleaning, and recalibrating thermostatic mixing valves to ensure they deliver safe, predictable hot water. TMVs blend hot and cold water to a safe temperature at taps, showers, and outlets - protecting users from scalding while reducing Legionella risk.

Correct servicing is essential because hot water stored at high temperatures can both scald and support bacterial growth if not managed correctly. A well-serviced TMV helps keep water at safe outlet temperatures while contributing to broader water safety strategies, including legionella control and regulatory compliance.

A full service includes temperature testing, internal cleaning, descaling, adjustment, and failsafe checks. It ensures the valve reacts quickly to temperature fluctuations and closes safely if the cold supply fails.

Key objectives:

-

Maintain safe delivery temperatures, especially for vulnerable users.

-

Ensure rapid failsafe operation to prevent scalding.

-

Comply with HSG274, NHS MES, and risk assessment recommendations

To learn more about TMV's, visit our blog: What Does TMV Stand For?

TMV Maintenance Explained

TMV maintenance is the routine care that keeps valves performing properly between full services. In most buildings, maintenance prevents small issues becoming temperature failures, user complaints, or repeated call outs. Routine TMV maintenance helps detect issues early and supports reliable failsafe operation, so valves continue blending hot and cold water within safe limits.

What TMV Maintenance Usually Includes

-

Visual checks for leaks, damage, or tampering

-

Outlet temperature spot checks at representative outlets

-

Simple cleaning of external strainers where fitted

-

Confirming isolation valves are usable and accessible

-

Reviewing recent risk assessment notes and previous results

TMV Maintenance vs TMV Servicing

A full TMV service is a deeper intervention. It involves internal inspection, descaling, recalibration, and formal failsafe checks. Maintenance is what keeps performance steady in between, and helps you spot trends early.

How Often Should TMVs Be Serviced?

Most TMVs require annual servicing, although the correct frequency should be set by your risk assessment and the type of building. In higher risk environments such as hospitals, care homes, schools and nurseries, more frequent checks are often recommended to support safety, compliance and record keeping..

You should arrange servicing if:

-

Outlets exceed safe temperature limits.

-

Users report fluctuating or inconsistent temperatures.

-

The valve has become stiff, slow to react, or blocked with scale.

-

A Legionella risk assessment recommends TMV servicing or more frequent checks.

Regular servicing helps prevent scalding incidents, keeps you compliant, and improves user safety across your building. Find out how often TMVs should be serviced in our detailed guide - How Often Should TMV's Be Serviced | Titan Water.

Compliance, Safety and Regulation

Thermostatic mixing valves are a critical part of water safety and hygiene in many buildings. In the UK, their installation, testing and maintenance are supported by a range of regulatory guidance, including the Water Supply (Water Fittings) Regulations, Building Regulations Part G and health and safety duties under HSE and relevant industry standards. Regular valve servicing and proper documentation help demonstrate due diligence and support compliance with these expectations.

What’s Involved in the TMV Servicing Process?

A professional thermostatic valve service includes:

-

Temperature testing – Checking outlet temperatures before and after servicing.

-

Internal cleaning and descaling – Removing debris, scale, and biofilm from internal mechanisms using appropriate descaler and disinfectant where required.

-

Replacement of worn components – Cartridges, strainers, or seals if necessary.

-

Recalibration – Adjusting the valve to achieve the correct blended temperature.

-

Failsafe verification – Ensuring the valve reacts correctly if hot or cold feed fails.

-

Flow rate check - Servicing also includes checking the flow rate at outlets to ensure the valve is operating correctly and delivering water within acceptable performance limits.

-

Record keeping and certification – Documenting all results for compliance and auditing.

Most servicing is completed with minimal disruption, and immediate repairs can usually be carried out on the spot.

See our blog post How To Service a TMV for further insight on the servicing process.

What Is the Difference Between TMV Failsafe Testing and TMV Servicing?

TMV failsafe testing and TMV servicing are closely related, but they are not the same thing. TMVs are designed with a fail safe function, meaning that if either the hot or cold water supply fails, the valve will shut down or significantly reduce flow to prevent the risk of scalding.

TMV failsafe testing is a specific safety check that confirms the valve shuts down correctly if the cold-water supply fails. This prevents scalding and is one of the most important compliance requirements under HSG274 and NHS engineering standards.

TMV servicing, on the other hand, is a full maintenance process. It includes temperature testing, internal cleaning, descaling, lubrication, cartridge checks, and recalibration. Servicing ensures the valve operates smoothly, blends water accurately, and reacts quickly to changes in supply conditions.

In simple terms:

-

TMV failsafe testing checks one critical safety function.

-

TMV servicing is a complete health check and tune-up of the valve.

Proper TMV servicing will always include failsafe testing, but failsafe testing alone does not replace the need for routine servicing. Carrying out both ensures the valve protects users, delivers stable temperatures, and remains fully compliant.

What Our Clients Say

Frequently Asked Questions

How much does TMV servicing typically cost?

The cost of servicing a thermostatic mixing valve varies depending on how many valves you have, how easily accessible they are, and whether any parts need replacing. On many sites, a standard service costs a few hundred pounds per valve, but prices rise if there’s heavy scale build-up, hard-to-access locations or additional maintenance is required.

Is TMV servicing a legal requirement in the UK?

In settings covered by health and safety law, regular valve servicing is effectively a requirement to meet regulatory duties. For higher risk environments such as healthcare, care homes and schools, statutes and guidance like HTM 04-01 and HSG 274 Part 2 expect thermostatic mixing valves to be installed, maintained, tested and documented on a regular basis.

How long does a TMV typically last before it needs replacement?

A thermostatic mixing valve can last many years if maintained correctly, but its lifespan depends on water quality, usage patterns and how consistently maintenance has been carried out. In normal water conditions with routine servicing, valves can often last 5–7 years or more. Hard water and heavy usage will shorten this.

What is the difference between a TMV2 and a TMV3?

TMV2 valves are designed for domestic settings such as private housing. TMV3 valves are tested to higher standards and are typically required in healthcare, education and commercial buildings where users may be more vulnerable and stricter temperature control is needed. For further reading, take a look at our dedicated blog - Difference Between TMV2 and TMV3 | Titan Water.

How long does a TMV service visit usually take?

Most individual TMV services can be completed within a few hours, depending on accessibility and how many valves are being assessed. If a valve requires replacement parts or additional work is found during inspection, this can extend the visit.

Can I do TMV servicing myself?

While simple visual checks and temperature spot tests can be done in-house, thorough servicing - including internal cleaning, descaling, recalibration and failsafe testing - should be carried out by a trained and competent professional with suitable tools and records for compliance.

What is the difference between an RPZ valve and a TMV?

A TMV controls water temperature at outlets to reduce scalding risk. An RPZ valve prevents backflow and protects the mains water supply from contamination. They perform different safety functions and are tested and maintained under separate regulations. Read our article that expands on the subject. The Difference Between a TMV and an RPZ Valve | Titan Water

Speak to an Expert

If you need support with TMV servicing, or want to discuss temperature checks, valve performance, or planned maintenance, you can speak directly with our team. We can help you understand what level of servicing is appropriate for your system and how it fits into your wider water hygiene responsibilities.

Explore Our Full Range of Services

Case Studies

When a thermostatic mixing valve begins to drift out of tolerance, it is usually a sign that the valve or the wider system is no longer performing as it should. At Titan, our engineers specialise in identifying these faults early and putting in place practical solutions that restore both safety and reliability.

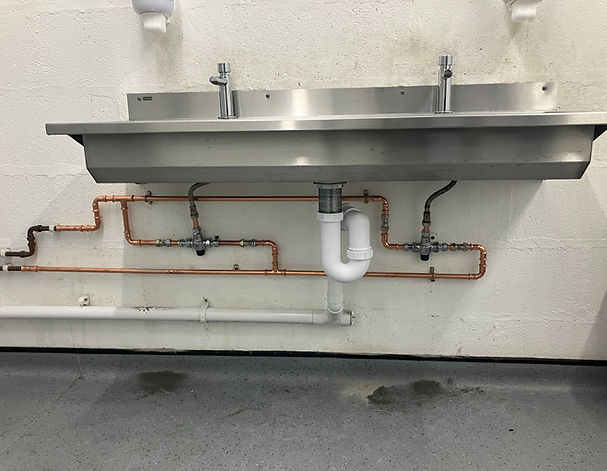

Take a look at our ‘TMV Replacement Case Study’ to see how we approach real world challenges when TMV's fail, from diagnosing underlying issues to delivering clean, compliant installations that stand the test of time.

_edited.png)